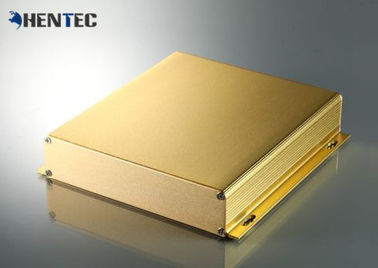

Anodized Aluminum Extrusions For Electronics / Electric Instrument Box

Hentec Industry Co., Ltd. focus on producing and manufacturing aluminum profile, aluminium extrusion, aluminium tube , aluminum window door and curtain wall profiles and aluminum frame for LED lighting with the largest extruder as 5,000 tonnage. We produce more than 100,000 tons aluminum products annually

Description:

1.Design ( drawing for qute and design files require )

2.Start with your CAD / PDF / 3D / Picture Drawing is the quickest and easiest way for made custom enclosures .Our engineers will according your requirement and design for you .

3.Machining :

Cut holes :Our standard cut tolerance is ±0.2 mm but tighter tolerances can be met when required. Extrusion is available as bars or cut-to-length (marked, deburred, and ready for installation).We can drill holes through any of our housings to meet your specific requirements.Our CNC processing center enables us to carry out difficult machining work to tight tolerances. From a nominal dimension (both size and location) our CNC equipment tolerance is ±0.1mm. We are capable of holding ±0.2 mm with high process capability on dimensions of size (hole diameter).

4.Surface Treatment

Our standard finish treatment have two different way , sanblast and brush

Brush number : 120# , 150 # , 180# ,240#

Sandblast number : 80# , 100#

Standard color : black , gray , silver , gold , blue , pink , red , green . any other color in need please feel free contact us .

5.Words print : made different words print method have silkscreen and engraving

Silkscree : can print several color

Applications:

Industry Aluminum profile used in cars, trains machinery ,electronics, medical and other industrial filed . In terms of hardware, machinery, electromechanical parts, solar PV products, aluminum frames are adopt as important auxiliary materials. We also have aluminum profiles for radiators, fitness machinery, buildings, lighting instrument, windpipes, oil pipelines, for instance.

Specifications:

1. Primary Technical Data

1)Chemical composition

|

Alloy

|

Si

|

Fe

|

Cu

|

Mn

|

Mg

|

Cr

|

Zn

|

Ti

|

Impurity

|

Al

|

|

6063

|

0.2-0.6

|

0.35

|

0.1

|

0.1

|

0.45-0.9

|

0.1

|

0.1

|

0.1

|

0.15

|

Rest

|

|

6061

|

0.4-0.8

|

0.7

|

0.15-0.4

|

0.15

|

0.8-1.2

|

0.04-0.35

|

0.25

|

0.15

|

0.15

|

Rest

|

|

6060

|

0.3-0.6

|

0.1-0.3

|

0.1

|

0.1

|

0.35-0.6

|

-

|

0.15

|

0.1

|

0.15

|

Rest

|

|

6005

|

0.6-0.9

|

0.35

|

0.1

|

0.1

|

0.40-0.6

|

0.1

|

0.1

|

0.1

|

0.15

|

Rest

|

2) Mechanical property

|

Alloy

|

Temper

|

Tensile strength

|

Yield strength

|

Elongation

|

|

6063

|

T5

|

≥ 160Mpa

|

≥ 110Mpa

|

≥ 8%

|

|

T6

|

≥ 205Mpa

|

≥ 180Mpa

|

≥ 8%

|

|

6061

|

T6

|

≥ 265Mpa

|

≥ 245Mpa

|

≥ 8%

|

2.Specifications:

Excellent material for smooth and subtle edges.

Elegant appearance.

Surface treatment: colorful anodized or electrostatic powder coated.

Suitable for constructions and other industrial purposes.

Customized surface finishes are welcome.

Competitive Advantage:

1) Engineering design and support.

2) Aluminum profiles deeply processing:cutting,punching,drilling,milling,and fabricating.

3) High Quality system, strictly inspection during production and whole inspection before package.

4) Good performance, product warranty for 15 years.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!