aluminum extrusion profiles

,aluminium extruded profiles

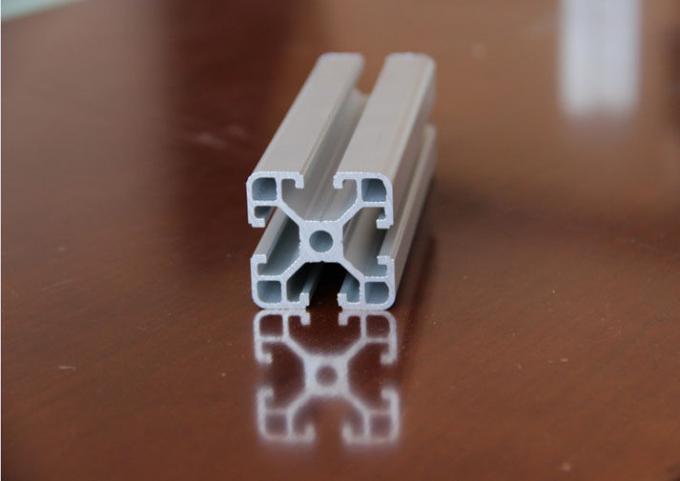

Silvery Anodized Industrial Aluminium Profile

Material:Aluminum

Alloy :6063,6061,6060,6005

Temper: T3, T4, T5, T6

Deep process: Milling, Drilling, Bending,Cutting

Description:

|

Item |

Customized Aluminum Industrial Profile |

|

Material |

Alloy 6063, 6061,6005 or according to customer’ s choice |

|

Temper |

T3, T4, T5, T6 |

|

Surface |

Anodize (clear, satin, bronze, black, golden, silver, other multicolor) , electrophoresis, powder coating, PVDF coating, wood grain painting, etc. |

|

MOQ |

1 ton. Usually 12 tons for a 20 feet container; 24 tons for a 40 feet container. |

|

Profile type |

Industry Aluminum profile used in cars, trains machinery ,trailers ,electronics, medical and other industrial filed . |

|

Machining |

High-precision machining 1. milling; 2. Drilling; 3. Bending; 4. Cutting ... |

|

Moulding |

1. Using our moulds, free; 2. Using customer’ s drawing, mould fee need to be paid . |

|

Standard |

Our Industrial Aluminium Profile Meet the China national standard GB/T5237-2004, GB/T6892-2000 |

|

FOB Port |

Shanghai, etc. |

1.Alloy :6063,6061,6005 or according to customer’ s choice

2.Material:Aluminum

3.Suface Treatment: Mill Finished,Anodized ,Electrophoretic coated,Powder spray coated,Fluorocarbon powder spray coated /PVDF Paint, Drawbench,Steel polished,Wood grain coated /Wooden transfer .

4.Deep process: Milling, Drilling, Bending,Cutting.

5.Application:

Industry Aluminum profile used in cars, trains machinery ,electronics, medical and other industrial filed . In terms of hardware, machinery, electromechanical parts, solar PV products, aluminum frames are adopt as important auxiliary materials. We also have aluminum profiles for radiators, fitness machinery, buildings, lighting instrument, windpipes, oil pipelines, for instance.

6.Color:clear, satin, bronze, black, golden, silver, other multicolor

7.Temper: T4, T5, T6 ,T66

Applications:

Industry Aluminum profile used in cars, trains machinery ,electronics, medical and other industrial filed . In terms of hardware, machinery, electromechanical parts, solar PV products, aluminum frames are adopt as important auxiliary materials. We also have aluminum profiles for radiators, fitness machinery, buildings, lighting instrument, windpipes, oil pipelines, for instance.

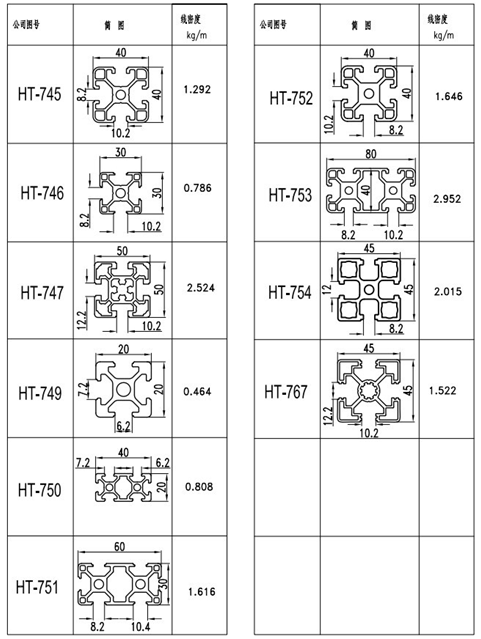

Specifications:

1.Primary Technical Data

1)Chemical composition

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Impurity |

Al |

|

6063 |

0.2-0.6 |

0.35 |

0.1 |

0.1 |

0.45-0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

|

6061 |

0.4-0.8 |

0.7 |

0.15-0.4 |

0.15 |

0.8-1.2 |

0.04-0.35 |

0.25 |

0.15 |

0.15 |

Rest |

|

6060 |

0.3-0.6 |

0.1-0.3 |

0.1 |

0.1 |

0.35-0.6 |

- |

0.15 |

0.1 |

0.15 |

Rest |

|

6005 |

0.6-0.9 |

0.35 |

0.1 |

0.1 |

0.40-0.6 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

2)Mechanical property

|

Alloy |

Temper |

Tensile strength |

Yield strength |

Elongation |

|

6063 |

T5 |

≥ 160Mpa |

≥ 110Mpa |

≥ 8% |

|

T6 |

≥ 205Mpa |

≥ 180Mpa |

≥ 8% |

|

|

6061 |

T6 |

≥ 265Mpa |

≥ 245Mpa |

≥ 8% |

Competitive Advantage:

1)Engineering design and support.

2)Aluminum profiles deeply processing:cutting,punching,drilling,milling,and fabricating.

3)High Quality system, strictly inspection during production and whole inspection before package.

4)Good performance, product warranty for 15 years.