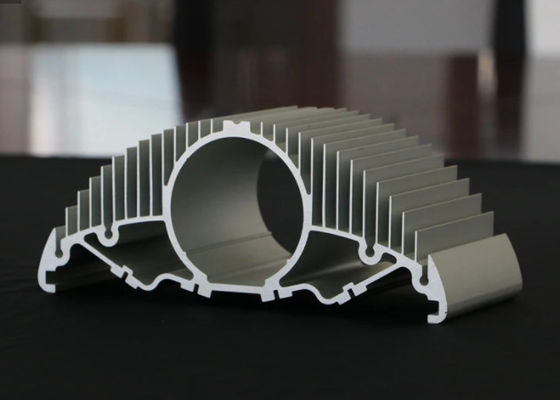

Large Air Cooling Aluminum Heat Sink Extrusion Profiles With Cnc Machining

1. Material: 6063,6061,6060,6005 or other

2. Temper: T4 ,T5 , T6 , T66

3. Finish: Mill finished, anodized,powder coated,polished,brushed,sand blasted

4. Various colors: Silver,bronze,black,gold,blue,grey,champagne,red,etc.

5. Machining: Cutting,punching,drilling,milling,bending,welding,CNC etc.

6. Various in styles and sizes:

A). Aluminum alloy bars: 6000 series, normal material such as 6063,6005,6061,6060, special materials such as 6082 etc.

B). Aluminum profiles:

-General aluminum profiles (various shapes of pipes/tubes, angles, T or U shapes etc.)

- Industrial aluminum profiles ( TV frames, Radiator profiles, Furniture, Ladder, Guide Rail, Leisure materials, Shower Room, Solar Module Frame, Motor Shell, Pipeline Integration etc.)

- Construction aluminum profiles ( Aluminum doors&windows, Sliding Windows, Curtain Wall Frame etc.)

7. Certification: ISO9001,SGS,ROHS

8. Strong technical development ability, can provide high intensity and high ductility aluminum profiles, to meet customers' different requirements.

9. OEM service available, customized design available

Quality Control: We operate the most strict quality system,the detection is from the material,production process to final product,and ensure the product quality.

Process: Die design--Die making--Smelting and alloying--Quality control--Extruding--Cutting--Heat treatment--Surface treatment--Welding--Packing

Packing: Packed with plastic film, then wrap by craft paper or EPE film.

Technology Supports

1. Engineering Design.

2. Quality Standard: China GB, according to the Drawing and the Customer's Details.

Specifications:

1. Primary Technical Data

1) Chemical composition

|

Alloy

|

Si

|

Fe

|

Cu

|

Mn

|

Mg

|

Cr

|

Zn

|

Ti

|

Impurity

|

Al

|

|

6063

|

0.2-0.6

|

0.35

|

0.1

|

0.1

|

0.45-0.9

|

0.1

|

0.1

|

0.1

|

0.15

|

Rest

|

|

6061

|

0.4-0.8

|

0.7

|

0.15-0.4

|

0.15

|

0.8-1.2

|

0.04-0.35

|

0.25

|

0.15

|

0.15

|

Rest

|

|

6060

|

0.3-0.6

|

0.1-0.3

|

0.1

|

0.1

|

0.35-0.6

|

-

|

0.15

|

0.1

|

0.15

|

Rest

|

|

6005

|

0.6-0.9

|

0.35

|

0.1

|

0.1

|

0.40-0.6

|

0.1

|

0.1

|

0.1

|

0.15

|

Rest

|

2) Mechanical property

|

Alloy

|

Temper

|

Tensile strength

|

Yield strength

|

Elongation

|

|

6063

|

T5

|

≥ 160Mpa

|

≥ 110Mpa

|

≥ 8%

|

|

T6

|

≥ 205Mpa

|

≥ 180Mpa

|

≥ 8%

|

|

6061

|

T6

|

≥ 265Mpa

|

≥ 245Mpa

|

≥ 8%

|

Competitive Advantage:

We can offer professional Manufacturing and exporting service, OEM/ODM for Metal & Plastic parts in China. All the parts manufactured by CNC Lathe & Milling Machine Center.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!