6063 / 6061 Standard Aluminum Extrusion Profiles Anodizing / Electrophoresis / Powder Painting

Our 4500T grade extrusion machine enable us to produce any section within 400*150mm and φ360.

Your drawings are definitely welcomed.

Price indication: basic aluminium ingot, extrusion cost, surfacing cost and extra.

We also supply fully assembled premium grade window&door systems.

Description:

| Product |

Aluminum Extrusion Profile |

| Material |

6063, 6061, 6005, 6082 |

| Temper |

T4/T5/T6/T66 |

| Surface treatment |

Powder Coating in RAL Color, Anodizing(AA10/15/20/25), Sandblasting, Brushing, Passivation, Silk screen, Mechanical/Chemical Polishing, Wood grain coated /Wooden transfer, Galvanise,(Nickel/Tin/Chrome/Copper) Plating, PVDF, Matt, etc. |

| Shape |

Flat/Square/Round/Hollow/Oval/Triangle

U type/L type/T type /H type |

| Deep Process |

Aluminium profile extruding, Precious milling, Cutting, Punching, Bending, Tapping, Drilling, CNC lathe etc.

Tolerance: length can be ±0.2mm, hole can be ±0.05mm. |

| Wall thickness |

> 0.9mm |

| Section size |

Square: ≤ 150*150mm |

| Rectangle:≤ 250*50mm |

| Round: ≤ ∅170mm |

| Package |

Inner plastic paper/PE paper interleaving each piece;

Outer fixed by plywood or pallets with shipping mark;

Or as required. |

| Delivery time |

15-25 days after deposit |

Process: Die design--Die making-Extruding--Cutting-- CNC Machining--Surface treatment --Packing

Applications:

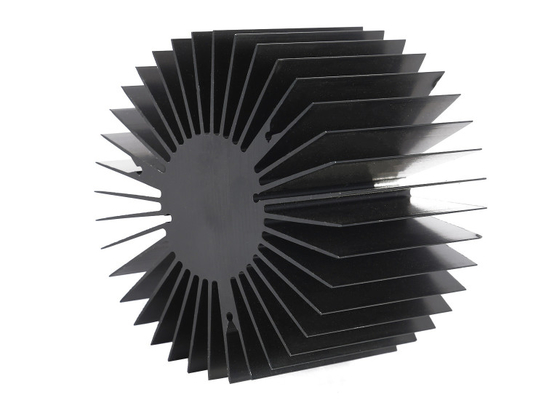

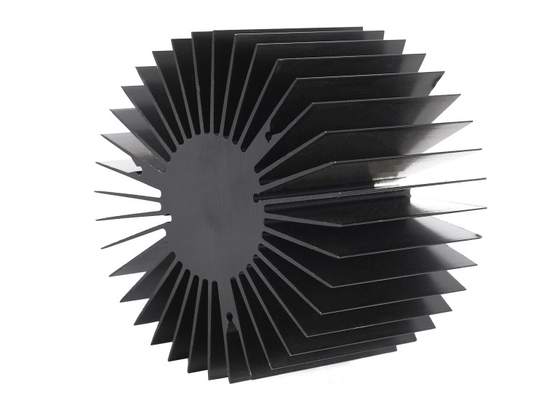

Industry Aluminum profile used in cars, trains machinery ,electronics, medical and other industrial filed . In terms of hardware, machinery, electromechanical parts, solar PV products, aluminum frames are adopt as important auxiliary materials. We also have aluminum profiles for radiators, fitness machinery, buildings, lighting instrument, windpipes, oil pipelines, for instance.

Specifications:

1) Chemical composition

|

Alloy

|

Si

|

Fe

|

Cu

|

Mn

|

Mg

|

Cr

|

Zn

|

Ti

|

Impurity

|

Al

|

|

6063

|

0.2-0.6

|

0.35

|

0.1

|

0.1

|

0.45-0.9

|

0.1

|

0.1

|

0.1

|

0.15

|

Rest

|

|

6061

|

0.4-0.8

|

0.7

|

0.15-0.4

|

0.15

|

0.8-1.2

|

0.04-0.35

|

0.25

|

0.15

|

0.15

|

Rest

|

|

6060

|

0.3-0.6

|

0.1-0.3

|

0.1

|

0.1

|

0.35-0.6

|

-

|

0.15

|

0.1

|

0.15

|

Rest

|

|

6005

|

0.6-0.9

|

0.35

|

0.1

|

0.1

|

0.40-0.6

|

0.1

|

0.1

|

0.1

|

0.15

|

Rest

|

2) Mechanical property

|

Alloy

|

Temper

|

Tensile strength

|

Yield strength

|

Elongation

|

|

6063

|

T5

|

≥ 160Mpa

|

≥ 110Mpa

|

≥ 8%

|

|

T6

|

≥ 205Mpa

|

≥ 180Mpa

|

≥ 8%

|

|

6061

|

T6

|

≥ 265Mpa

|

≥ 245Mpa

|

≥ 8%

|

Competitive Advantage:

1) Engineering design and support.

2) Aluminium profiles deeply processing:cutting,punching,drilling,milling,and fabricating.

3) High Quality system, strictly inspection during production and whole inspection before package.

4) Good performance, product warranty for 15 years.

Aluminum profile production process:

It mainly includes three processes of casting, extrusion and coloring (coloring mainly includes: oxidation, electrophoretic coating, fluorocarbon coating, powder coating, wood grain transfer, etc.).

1. Melting and casting is the first process of aluminum production.

The main process is:

(1) Ingredients: Calculate the amount of various alloy components according to the specific alloy grades that need to be produced, and reasonably match various raw materials.

(2) Smelting: The prepared raw materials are added to the melting furnace for melting according to the process requirements, and the impurities and gases in the melt are effectively removed by degassing and slag refining means.

(3) Casting: The molten aluminum liquid is cooled and cast into various round casting rods under a certain casting process condition through a deep well casting system.

2. Extrusion:

Extrusion is the means of profile forming. Firstly, the mold is designed and manufactured according to the section of the profile product, and the heated round cast rod is extruded from the mold by an extruder. The commonly used grade 6063 alloy is also subjected to an air-cooling quenching process and an artificial aging process after extrusion to complete the heat treatment strengthening. Different grades of heat treatable reinforced alloys have different heat treatment regimes.

3. Coloring (here mainly on the oxidation process)

Oxidation: The extruded aluminum alloy profile has a low surface corrosion resistance and must be surface treated by anodizing to increase the corrosion resistance, wear resistance and appearance of the aluminum.

The main process is:

(1) Surface pretreatment: The surface of the profile is cleaned by chemical or physical means to expose a pure substrate to facilitate the obtaining of a complete and dense artificial oxide film. It is also possible to obtain a specular or matt (matte) surface by mechanical means.

(2) Anodizing: After surface pretreatment, under certain process conditions, the surface of the substrate is anodized to form a dense, porous, strong adsorption film.

(3) Sealing: The pores of the pores of the porous oxide film formed by anodization are closed, so that the oxide film is prevented from being contaminated, and the corrosion resistance and wear resistance are enhanced. The oxide film is colorless and transparent. By using the strong adsorption property of the oxide film before sealing, some metal salts are adsorbed and deposited in the pores of the film, so that the appearance of the profile shows many colors other than the natural color (silver white), such as black, bronze, Gold and stainless steel.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!