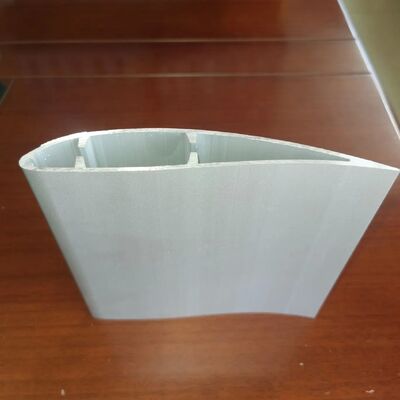

Custom Aluminum Extrusion Fan Blade Profiles

MetalPlus specializes in designing and manufacturing custom industrial aluminum extrusion fan blade profiles using AA6060, AA6063, AA6005, and AA6061 alloys with sandblast anodizing surface treatment.

We supply zero-defect aluminum profiles with custom design capabilities for industrial fan applications.

Product Specifications

| Alloy |

AA6063-T5, AA6061-T6 |

| Standard |

GB/75237-2004 |

| Specification |

Customized (OEM) |

| Design |

Custom dies based on customer samples or drawings |

| Mold Time |

Approximately 10 days after drawing confirmation |

| Length |

Custom cut to customer requirements |

| Thickness |

Customized to customer specifications |

| MOQ |

500 kg per design |

| H.S. Code |

7604210000 |

| Origin |

Shanghai, China |

| Packing |

Cover film or EP foam, bundled with shrink film/carton paper |

| Delivery Time |

20-25 days after order confirmation |

| Loading Port |

Shanghai |

| Payment Terms |

30% deposit, balance before shipment |

Technical Data

Chemical Composition

| Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Impurity |

Al |

| 6063 |

0.2-0.6 |

0.35 |

0.1 |

0.1 |

0.45-0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

| 6061 |

0.4-0.8 |

0.7 |

0.15-0.4 |

0.15 |

0.8-1.2 |

0.04-0.35 |

0.25 |

0.15 |

0.15 |

Rest |

| 6060 |

0.3-0.6 |

0.1-0.3 |

0.1 |

0.1 |

0.35-0.6 |

- |

0.15 |

0.1 |

0.15 |

Rest |

| 6005 |

0.6-0.9 |

0.35 |

0.1 |

0.1 |

0.40-0.6 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

Mechanical Properties

| Alloy |

Temper |

Tensile Strength |

Yield Strength |

Elongation |

| 6063 |

T5 |

≥ 160 MPa |

≥ 110 MPa |

≥ 8% |

| 6063 |

T6 |

≥ 205 MPa |

≥ 180 MPa |

≥ 8% |

| 6061 |

T6 |

≥ 265 MPa |

≥ 245 MPa |

≥ 8% |

Surface Treatment Specifications

| Class |

Min-Avg Film Thickness (μm) |

Min-Part Film Thickness (μm) |

Acid-Resistant CASS |

Abrasion Resistance (S) |

Abrasion Resistance (h) |

Class |

Abrasion (f, g/μm) |

| AA10 |

10 |

8 |

16 |

≥9 |

≥50 |

≥300 |

| AA15 |

15 |

12 |

32 |

≥9 |

≥75 |

≥300 |

| AA20 |

20 |

16 |

56 |

≥9 |

≥100 |

≥300 |

| AA25 |

25 |

20 |

72 |

≥9 |

≥125 |

≥300 |

Technical Support & Services

- Custom design services including CAD drawings and 3D models

- Professional R&D team for design optimization and cost reduction

- One-stop production from design to surface treatment

- Quality control throughout manufacturing process

Manufacturing Capabilities

Extrusion

44 aluminum extrusion lines with maximum outer diameter capacity of 350mm, including a 6800-ton extruder for profiles up to 600mm diameter.

Anodizing

6 anodizing production lines providing uniform oxidation film thickness in various colors including silver, black, gold, champagne, and imitation steel.

Painting

4 powder spraying lines using Gema Switzerland nozzles with environmentally friendly, durable paints.

CNC Machining

Advanced machining equipment including 12 PRATIC machining centers, automatic cutting machines, and 30 punching machines.

Packing & Shipping

Manual packaging with protective film/foam and shrink wrapping. Strict warehouse management with quality inspection before delivery.

Certifications & Quality

Company History & Projects

Established in 2004, MetalPlus has grown to become a trusted supplier for major international clients including Panasonic, LG, and European manufacturers.

Notable Projects

Soccer City Stadium, Johannesburg - Main aluminum supplier for Africa's largest stadium

Lobster Trailers - Custom aluminum profile supplier for Nordic trailer manufacturer

School furniture components for educational projects

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!