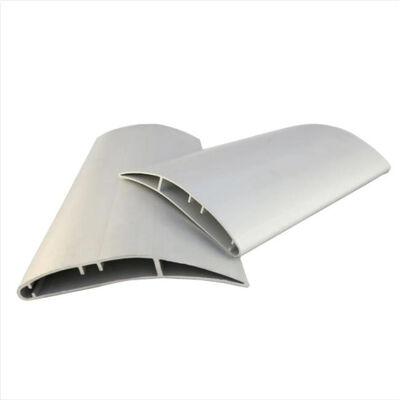

Powder Painting Sandblasting Anodized Aluminum Fan Blade

Custom aluminum fan blades manufactured with precision machining and multiple surface treatment options for industrial applications.

Product Specifications

| Material |

6063 aluminum profile |

| Mechanical Processing |

Aluminium profile extruding, Precision milling, Cutting, Punching, Bending, Tapping, Drilling, CNC lathe |

| Tolerance |

Length: ±0.2mm, Holes: ±0.05mm |

| Surface Treatment |

Powder Coating (RAL Color), Anodizing (AA10/15/20/25), Sandblasting, Brushing, Passivation, Silk screen, Mechanical/Chemical Polishing, Wood grain coated/Wooden transfer, Galvanizing, (Nickel/Tin/Chrome/Copper) Plating, PVDF, Matt |

| Color Customization |

Wooden Grain, Aluminium Silver, Brilliant Black, Cream White, Chocolate Brown, Bronze, Champagne, Golden Yellow |

| Section Size |

Square: ≤ 150×150mm, Rectangle: ≤ 250×50mm, Round: ≤ ∅170mm |

| Package |

Inner plastic paper/PE paper interleaving each piece; Outer fixed by plywood or pallets with shipping mark; Or as required |

| Delivery Time |

15-25 days after deposit |

Manufacturing Advantages

We export the majority of our customized products to the United States and Europe, where our customers have become regular clients. Our extensive experience enables us to easily satisfy customer requirements.

- Over 17 years of manufacturing experience in aluminum extrusion

- Strong design capabilities with fast extrusion, CNC machining, milling, and turning services

- Complete metal processing capabilities including laser cutting, CNC bending, and welding

- Comprehensive quality control throughout the manufacturing process for long-term stability and excellent quality

Technical Support Services

Custom Design & Development

Based on customer requirements, we design extruded profile appearances, provide CAD drawings and 3D models for confirmation, customize molds, and extrude aluminum profiles to meet specifications.

Design Optimization

For customers with design capabilities, our R&D team analyzes and optimizes designs using extrusion processing experience to reduce production costs and improve product performance.

One-Stop Manufacturing

Comprehensive service model including product design, custom molds, aluminum bar melting and casting, extrusion profiling, precision machining, and surface treatment.

Factory Equipment Capabilities

Extrusion

Equipped with 44 aluminum extrusion lines, we produce commercial and industrial aluminum profiles with maximum outer diameter of 350mm. Our largest 6800-ton extruder handles complex industrial profiles up to 600mm diameter for applications including radiators, fan blades, motor enclosures, and solar cell frames.

Anodizing

Six anodizing production lines create uniform aluminum oxide layers for improved corrosion resistance, hardness, and wear resistance. Available in silver, black, gold, champagne, and imitation steel colors with custom options.

Painting

Four powder spraying lines equipped with Gema Switzerland nozzles using environmentally friendly, durable paint with strong adhesion and color retention.

CNC Machining

Advanced machining equipment operated by experienced technicians ensures precision and quality. Capabilities include 12 PRATIC machining centers for complex profiles up to 6 meters, automatic cutting machines, 30 punching machines, bending machines, and milling equipment.

Packing & Shipping

Finished products are manually packaged and ready for delivery. Strict warehouse management procedures ensure quality control with detailed records and inspections.

Certifications

Company History

2004: Recognized brand of building industry material market

2006: Certificate for product exemption from quality surveillance inspection and ISO9001 certification

2009: Advanced company, Jiangsu famous brand certificate, and credible product of quality in Jiangsu Province

2012: Established business relationships with Panasonic and LG

2015: Innovative producer and supplying partner for European clients

2017: Developed new baseboard heater products

2019: Cooperated with world's largest heater manufacturers as aluminum shell supplier

2023: Expanding overseas distribution network for win-win market benefits

Featured Projects

Soccer City Stadium, Johannesburg: As the main aluminum supplier for Africa's largest stadium (94,000 seats), we contributed to this major construction project that received unanimous praise.

Lobster Trailers: Partnership with Nordic trailer giant featuring design optimization and precision processing to minimize costs and improve performance.

School Project: Supplied aluminum legs for school desks, supporting local customers in winning project bids through strong design capabilities and mature technology.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!