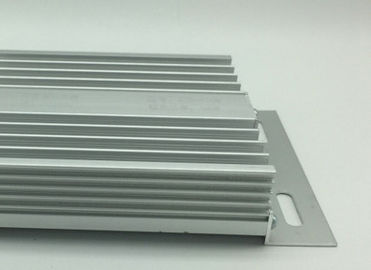

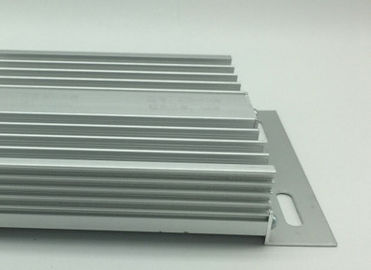

Mill Finished Aluminum Electrical Shell / With Cutting , Drill , Punching , Milling

Introduction Of Constmart Profile:

1. Material: 6063,6061,6060,6005 etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue,grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

6. Various in styles and sizes:

A) Aluminum alloy bars: ranging from 6000 series, normal material such as 6063,6005,6061,6060, special materials such as 6082 etc.

B) Aluminum profiles:

---General aluminum profiles (various shapes of pipes/tubes, angles, T or U shapes etc.)

--- Industrial aluminum profiles

--- Construction aluminum profiles

7. Strong technical development ability, can provide high intensity and high ductility aluminum profiles, to meet customers' different requirements.

8. OEM service available, customized design available

Description:

| Item |

Aluminum Extrusion bar |

| Material |

Alloy 6063, 6061 or according to customer’ s choice |

| Temper |

T3, T4, T5, T6 |

| Surface |

Anodize (clear, satin, bronze, black, golden, silver, other multicolor) , electrophoresis, powder coating, PVDF coating, wood grain painting, etc. |

| MOQ |

1 ton. Usually 12 tons for a 20 feet container; 24 tons for a 40 feet container. |

| Profile type |

Industry Aluminum profile used in cars, trains machinery ,trailers ,electronics, medical and other industrial filed . |

| Machining |

1. milling; 2. Drilling; 3. Bending; 4. Cutting ... |

| Moulding |

1. Using our moulds, free; 2. Using customer’ s drawing, opening mould fee need to be paid . |

| Certificate |

ISO14001:2004, ISO9001:2000 |

| FOB Port |

Shanghai, etc. |

Applications:

Industry Aluminum profile used in cars, trains machinery ,electronics, medical and other industrial filed . In terms of hardware, machinery, electromechanical parts, solar PV products, aluminum frames are adopt as important auxiliary materials. We also have aluminum profiles for radiators, fitness machinery, buildings, lighting instrument, windpipes, oil pipelines, for instance.

Specifications:

1.Primary Technical Data

1)Chemical composition

| Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Impurity |

Al |

| 6063 |

0.2-0.6 |

0.35 |

0.1 |

0.1 |

0.45-0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

| 6061 |

0.4-0.8 |

0.7 |

0.15-0.4 |

0.15 |

0.8-1.2 |

0.04-0.35 |

0.25 |

0.15 |

0.15 |

Rest |

| 6060 |

0.3-0.6 |

0.1-0.3 |

0.1 |

0.1 |

0.35-0.6 |

- |

0.15 |

0.1 |

0.15 |

Rest |

| 6005 |

0.6-0.9 |

0.35 |

0.1 |

0.1 |

0.40-0.6 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

2)Mechanical property

| Alloy |

Temper |

Tensile strength |

Yield strength |

Elongation |

| 6063 |

T5 |

≥ 160Mpa |

≥ 110Mpa |

≥ 8% |

| T6 |

≥ 205Mpa |

≥ 180Mpa |

≥ 8% |

| 6061 |

T6 |

≥ 265Mpa |

≥ 245Mpa |

≥ 8% |

Competitive Advantage:

1)Engineering design and support.

2)Aluminium profiles deeply processing:cutting,punching,drilling,milling,and fabricating.

3)High Quality system, strictly inspection during production and whole inspection before package.

4)Good performance, product warranty for 15 years.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!