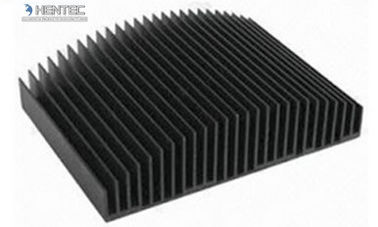

6063 Aluminum Heatsink Extrusion Profiles For Water Cooler / Electronic Radiator / Automatic Industry

Aluminum can be very popular in the radiator industry, and can shine here, thanks to its excellent performance. MetalPlus Industrial adopts superior quality aluminum materials on the radiator casting road, which can lay a solid foundation for product quality from the source, and then use professional and exquisite craftsmanship to produce aluminum radiators that can be adapted to various fields and exert practical effects. , To solve the heat dissipation problem of various industries.

Description :

Aluminum Extruded Heat Sink

Material : Aluminum Alloy 6063-T5

Surface Treatment : Alodine , Anodize,Powder Painting , Electrophoresis or customized .

Color : Silvery , Black or customized .

Quality Control :We operate the most strict quality system,the detection is from the material,production process to final product,and ensure the product quality.

Process: Die design--Die making-Extruding--Cutting-- CNC Machining--Surface treatment --Packing

Packing: Packed with plastic film and wooden case with is suitable for Sea Shipment or Air Shipment

Technology Supports :

Our company has more than 600 employees, 50 R & D and structural design personnel, we are able to arrange the initial design drawing and the heat sink specification within the shortest time .

Once the design has been signed off, the quotation and actual lead me can be informed to the client.

Then move to the sample stage, Metalplus will extrude the profiles and CNC machine sample to test . And once approved , the prototype can be sent to the client .

After the prototype has been confirmed , we will follow the production

It is the cheapest customisation method to achieve high performance of a heat sink.

Application

It is believed that as long as people who have used electronic products know that heat dissipation problems will be involved in such products as video card, CPU, chassis power supply, etc., such products will have a radiator, generally aluminum alloy electronic radiator, which is only the application of radiator in ordinary civil products.

In addition, there are many industrial high-power devices that we don't pay much attention to, but are very important. They will also be used in electronic radiators. The main applications of high-power electronic radiator: Audio Equipment ,UPS power supply, EPS power supply, inverter, transformer, monocrystalline silicon, polycrystalline silicon, battery pack, new energy electronic controller, charging pile, inverter power supply, switching power supply,IP power supply, welding machine, communication transmitter, base station, control cabinet, power regulator, thyristor, etc.

Advantage :

The aluminum profile is made of pure aluminum or aluminum alloy. Through smelting, cutting, extrusion and other processes, metal panels with different cross-sectional shapes can be formed, and then can be processed under surface treatment processes such as wire drawing, sandblasting, electroplating, laser screen printing, and anodizing. It can be cast into a radiator shell with exquisite surface, superior and stable performance. As a raw material, aluminum profiles mainly have the following characteristics

1. Light weight

2. Corrosion resistance

3. Thermal conductivity

4. Non-magnetic

5. Plasticity

Specifications:

1. Primary Technical Data

1) Chemical composition

| Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Impurity |

Al |

| 6063 |

0.2-0.6 |

0.35 |

0.1 |

0.1 |

0.45-0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

| 6061 |

0.4-0.8 |

0.7 |

0.15-0.4 |

0.15 |

0.8-1.2 |

0.04-0.35 |

0.25 |

0.15 |

0.15 |

Rest |

| 6060 |

0.3-0.6 |

0.1-0.3 |

0.1 |

0.1 |

0.35-0.6 |

- |

0.15 |

0.1 |

0.15 |

Rest |

| 6005 |

0.6-0.9 |

0.35 |

0.1 |

0.1 |

0.40-0.6 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

2) Mechanical property

| Alloy |

Temper |

Tensile strength |

Yield strength |

Elongation |

| 6063 |

T5 |

≥ 160Mpa |

≥ 110Mpa |

≥ 8% |

| T6 |

≥ 205Mpa |

≥ 180Mpa |

≥ 8% |

| 6061 |

T6 |

≥ 265Mpa |

≥ 245Mpa |

≥ 8% |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!