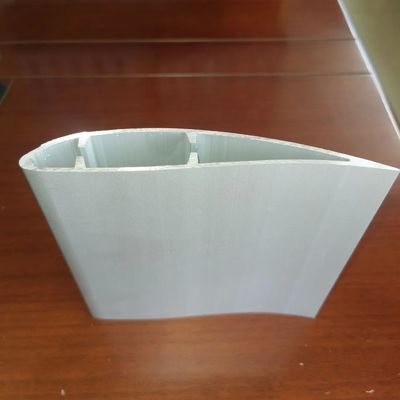

Custom Aluminum Fan Blade Profile 6063/6061

MetalPlus specializes in designing and manufacturing custom industrial aluminum extrusion fan blade profiles to meet your specific performance and design requirements. With extensive expertise in fan blade profile design, tooling, prototyping, testing, balancing, and large-scale production, we deliver precision-engineered solutions.

Since 2007, our 6800-ton extrusion machine enables production of profiles with maximum diameters up to 600mm, perfect for large-section fan blades.

Product Specifications

| Product Name |

Aluminum Fan Blade |

| Material |

6063 /6061 aluminium alloy |

| Temper |

T5/T6 |

| Surface Treatment |

Mill finish, powder coating, anodizing, wooden grain coating, polishing, electrophoresis, PVDF, sand blasting, etc. |

| Size |

Customized to customer requirements |

| Width |

90mm to 250mm or customized |

| Color |

Natural silver, Black, or custom colors |

| Deep Processing |

Cutting, Drilling, Threading, Bending, etc. |

| Application |

Building, Industry, Machinery |

| Certification |

ISO9001 |

Technical Data

Chemical Composition

| Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Impurity |

Al |

| 6063 |

0.2-0.6 |

0.35 |

0.1 |

0.1 |

0.45-0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

| 6061 |

0.4-0.8 |

0.7 |

0.15-0.4 |

0.15 |

0.8-1.2 |

0.04-0.35 |

0.25 |

0.15 |

0.15 |

Rest |

Mechanical Properties

| Alloy |

Temper |

Tensile Strength |

Yield Strength |

Elongation |

| 6063 |

T5 |

≥ 160Mpa |

≥ 110Mpa |

≥ 8% |

| 6063 |

T6 |

≥ 205Mpa |

≥ 180Mpa |

≥ 8% |

| 6061 |

T6 |

≥ 265Mpa |

≥ 245Mpa |

≥ 8% |

Technical Support

- Custom design services including CAD drawings and 3D models for profile confirmation

- Design optimization by our R&D team to reduce costs and improve performance

- Complete "one-stop" production from design to surface treatment with strict quality control

Manufacturing Capabilities

Extrusion

With 44 aluminum extrusion lines including a 6800-ton unit, we produce industrial profiles up to 600mm diameter for applications including radiators, fan blades, motor enclosures, and solar cell frames.

Anodizing

Our 6 anodizing lines produce uniform oxidation films in various colors (silver, black, gold, champagne) with enhanced corrosion resistance and hardness. Strict inspection ensures zero color variation.

CNC Machining

Our advanced machining center includes 12 PRATIC machining centers for complex profiles up to 6 meters, 30 punching machines (50-100 ton capacity), and precision bending equipment.

Quality Assurance

Finished products undergo manual packaging and strict warehouse management with detailed records and inspection before delivery.

Certifications

Company Milestones

- 2004: Recognized Brand of Building Industry Material Market

- 2006: ISO9001 Certification

- 2009: Jiangsu Famous Brand Certificate

- 2012: Established partnerships with Panasonic and LG

- 2019: Supplier for world's largest heater manufacturers

Notable Projects

Soccer City Stadium, Johannesburg

As main aluminum supplier for Africa's largest stadium (94,000 seats), our materials contributed to this landmark project's success.

Lobster Trailers

Collaboration with this Nordic trailer giant showcases our design optimization and precision manufacturing capabilities.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!