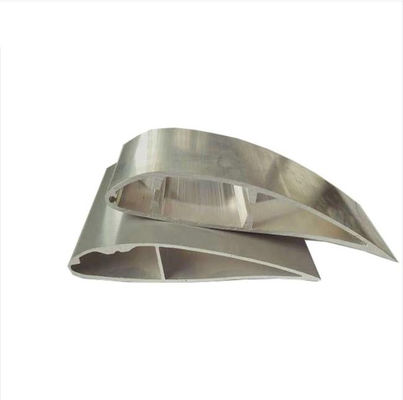

Aluminum Fan Blade Extrusion Profile Customized Cooling Tower Use

Metalplus specializes in aluminum industrial profile design and manufacturing with a production base of more than 100,000 square meters and annual capacity exceeding 100,000 tons.

Products Navigation

Product Specifications

| Feature |

Details |

| Material |

6063 aluminum profile |

| Processing |

Extruding, milling, cutting, punching, bending, tapping, drilling, CNC lathe |

| Tolerance |

Length: ±0.2mm, Hole: ±0.05mm |

| Surface Treatment |

Powder coating, anodizing, sandblasting, brushing, polishing, plating, etc. |

| Color Options |

Wood grain, silver, black, white, brown, bronze, champagne, yellow, etc. |

| Section Size |

Square: ≤150×150mm, Rectangle: ≤250×50mm, Round: ≤∅170mm |

| Packaging |

Inner plastic/PE paper, outer plywood/pallets with shipping mark |

| Delivery Time |

15-25 days after deposit |

Our Advantages

We export the majority of our customized products to the United States and Europe, where our customers have become regulars. With over 17 years of experience in aluminum extrusion, we can easily satisfy customers' needs.

- 17+ years of aluminum extrusion manufacturing experience

- Strong design and extrusion capabilities with fast turnaround

- Complete metal processing equipment including CNC machining, laser cutting, bending, and welding

- Strict quality control throughout the manufacturing process

Technical Support

Our comprehensive service includes design assistance, CAD drawings, 3D models, mold customization, and full production capabilities:

- Design assistance and optimization for cost reduction and performance improvement

- One-stop service from design to surface treatment with quality control at every stage

- Control of raw material alloy composition and production accuracy

Factory Equipment

Extrusion

With 44 aluminum extrusion lines including a 6800-ton unit, we produce profiles up to 350mm diameter for various applications including radiators, fan blades, motor enclosures, and solar frames.

Anodizing

Our 6 anodizing lines produce uniform oxidation films in various colors with strict quality inspection to ensure consistency.

Painting

4 powder spraying lines using Gema Switzerland nozzles with environmentally friendly, durable paints.

CNC Machining

Advanced equipment including 12 PRATIC machining centers, automatic cutting machines, 30 punching machines, and bending machines for precise processing.

Packing & Shipping

Strict warehouse management with manual packaging and quality inspection before delivery.

Certifications

Company History

- 2004: Recognized brand of building industry materials

- 2006: ISO9001 certification

- 2009: Jiangsu Famous Brand Certificate

- 2012: Partnership with Panasonic and LG

- 2015: Innovative supplier for European clients

- 2017: Developed baseboard heaters

- 2019: Supplier for world's largest heater manufacturers

- 2023: Expanding global distribution network

Notable Projects

Soccer City Stadium, Johannesburg: Main aluminum supplier for Africa's largest stadium (94,000 seats).

Lobster Trailers: Aluminum components supplier for Nordic trailer manufacturer with design optimization services.

School Furniture Project: Supplied aluminum legs for school desks, assisting local customer with tender success.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!