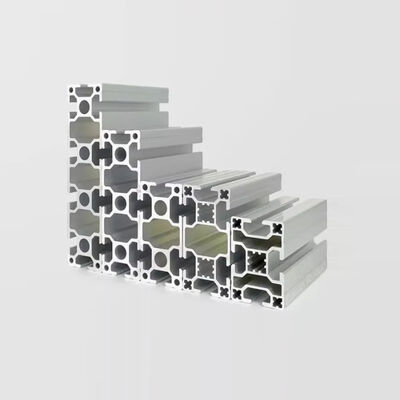

T-Slot Aluminum Framing Systems

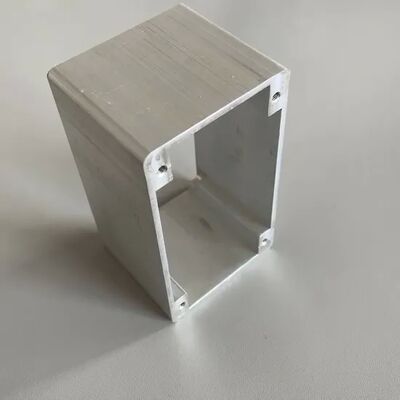

MetalPlus's versatile t-slot aluminum framing systems provide ideal solutions for machine bases and frames, linear slide systems, safety guarding and enclosures, worktables, structural framing, and materials handling applications.

Product Specifications

Aluminum T-Slot Profile Specifications

| Specification |

Details |

| Size Series |

10/15/20/25/30/35/40/45/50/55/60/65/70/75/80/85 series and Custom Made sizes |

| Grade |

6061/6063/6082-T5/T6 |

| Available Machinery |

Punching machines (50T-100T+), CNC machines, Electric Pulse, Wire EDM, Milling, Drilling, Grinding, Tapping, Riveting, Bending, and Shearing equipment |

| Certification |

ISO9001 |

| Material |

6063, 6061 T5/T6 Aluminum Alloy |

| Surface Treatment |

Polishing, Sandblasting, Painting, Powder coating, Galvanizing, Chrome plating, Anodizing (White/Black), E-coating, T-Coating - customized to requirements |

We utilize Germany-imported machinery and professional engineering expertise to provide high-precision custom aluminum alloy extrusion and profiles according to your drawings or samples.

Applications

- Heavy duty racks and storage systems

- Robot safety fencing and industrial safety enclosures

- Industrial material handling trolleys and carts

- Work benches and production tables

- Material handling systems and conveyor frames

- Parts racks and storage solutions

- Machine guarding and protective enclosures

- Lean manufacturing tools and equipment

- Rolling carriages and mobile workstations

- Flexible work cells and production lines

- Machine bases and structural frames

- Clean room framework and structures

- Custom mechanical equipment components

Aluminum Profile Advantages

- 100% recyclable and contamination-free

- Economical and reusable

- Lightweight and easy to assemble

- Wide range of applications

- High gloss finish with varying load capacities

Technical Data

Chemical Composition

| Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Impurity |

Al |

| 6063 |

0.2-0.6 |

0.35 |

0.1 |

0.1 |

0.45-0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

| 6061 |

0.4-0.8 |

0.7 |

0.15-0.4 |

0.15 |

0.8-1.2 |

0.04-0.35 |

0.25 |

0.15 |

0.15 |

Rest |

| 6060 |

0.3-0.6 |

0.1-0.3 |

0.1 |

0.1 |

0.35-0.6 |

- |

0.15 |

0.1 |

0.15 |

Rest |

| 6005 |

0.6-0.9 |

0.35 |

0.1 |

0.1 |

0.40-0.6 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

Mechanical Properties

| Alloy |

Temper |

Tensile Strength |

Yield Strength |

Elongation |

| 6063 |

T5 |

≥ 160Mpa |

≥ 110Mpa |

≥ 8% |

| 6063 |

T6 |

≥ 205Mpa |

≥ 180Mpa |

≥ 8% |

| 6061 |

T6 |

≥ 265Mpa |

≥ 245Mpa |

≥ 8% |

Technical Support Services

Custom Design Support

We provide comprehensive design services including CAD drawings and 3D models, custom mold creation, and aluminum profile extrusion tailored to your specific requirements.

Design Optimization

Our professional R&D team analyzes and optimizes customer designs using extrusion processing expertise to reduce production costs and enhance product performance.

One-Stop Production

Complete service model covering product design, mold customization, aluminum casting, extrusion profiling, precision machining, and surface treatment for quality control.

Manufacturing Capabilities

Extrusion Facilities

With 44 aluminum extrusion lines including PLC control systems and a 6800-ton extruder, we produce commercial and industrial profiles up to 600mm diameter for applications including radiators, fan blades, motor enclosures, and solar cell frames.

Anodizing Process

Six anodizing production lines create uniform oxidation films in silver, black, gold, champagne, and imitation steel colors, enhancing corrosion resistance, hardness, and wear resistance.

Painting & Coating

Four powder spraying lines equipped with Gema Switzerland nozzles using environmentally friendly paints with strong adhesion and durable color retention.

CNC Machining

Advanced machining equipment including 12 PRATIC machining centers for profiles up to 6 meters, automatic cutting machines, 30 punching machines (50-100 tons), bending machines, and milling equipment for complex profile processing.

Quality Assurance & Packaging

Strict warehouse management with manual packaging, section-based storage, comprehensive transaction recording, and pre-delivery examination ensures product quality and traceability.

Certifications

Company History

2004

Recognized brand of the building industry material market

2006

Certificate for product exemption from quality surveillance inspection and ISO9001 certification

2009

Advanced company recognition, Jiangsu famous brand certificate, and credible product of quality in Jiangsu Province

2012

Established business relationships with Panasonic and LG

2015

Became innovative producer and supplying partner for German client

2017

Developed new baseboard heater products

2019

Cooperated with world's largest heater manufacturers supplying aluminum shells

2023

Expanding overseas distributor network for win-win market benefits

Notable Projects

Soccer City Stadium, Johannesburg

As the main aluminum supplier for Africa's largest stadium (94,000 seats), we contributed to this major South African construction project that received unanimous praise upon completion.

Lobster Trailers Partnership

Collaboration with Nordic trailer giant featuring design analysis, improvement, and processing with advanced equipment to minimize production costs and enhance product performance.

School Furniture Project

Supplied aluminum legs for school desks, supporting local customer Dadn's successful bid with strong design capabilities and mature technical expertise.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!