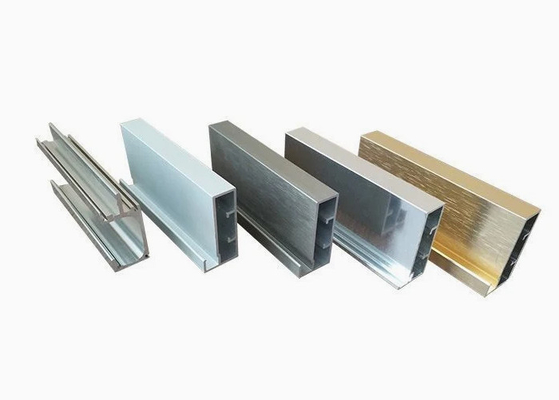

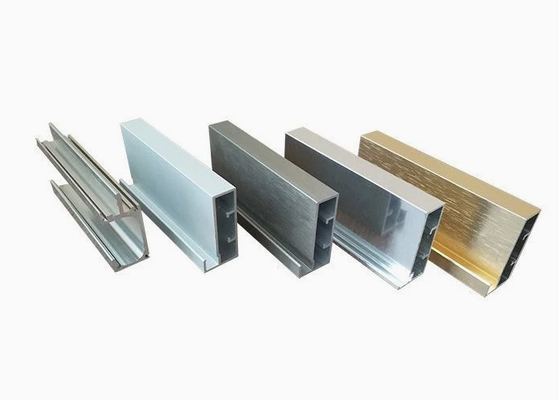

Bright Anodizing Industrial Aluminium Extrusion Profiles Customized CNC Machining

MetalPlus (Hentec Factroy) is a professional manufacturer that holds multiple machining technologies and has its own brand, CNC precision machining etc. There are 100 sets of machining equipment, 50 sets of them are machining & detection instruments with high configuration & high precision, assuring all products to be best quality and most accurate. MetalPlus (Hentec Factory) has built its own team with designing, producing, after sales services integrated, to meet different requirements of each customer.

Business type:Real Big Manufacturer & Exporter with 22 years experience

Production Standard:Architecture Profile : GB 5237-2008 ;Industry Profile : GB/T6892-2008

Main products :luminum extrusion profiles for architectural & industrial,Different aluminum profile sections for different applications .

Main Product Finishes :Mill finish,powder coating,anodized color,wooden pattern,Polyvinylidene Fluoride (PVDF)-Coating,Machine Polishing, Chemical Polishing, Mirror Polishing, Brushing Finish,thermal insulation of barrier strip,thermal insulation of filling-polyurethane

Packing:Kraft paper, EPE Fram, Shrink film, Carton Box,Wooden box etc,Customized package is available.

Sample time :10-15 days after drawing confirmed and mold cost paid.

Delivery time:35 days after deposit received.

Port:Shanghai Port

Order,payment,terms,shipment

1, Minimum order: 500kg per trial order 1 piece of sample free of charge provided by approval and kept for future mass production.

2, Sample Lead Time: 25 working days(15 days for making the tool and 10 days making the samples. Before sending the samples to customer, samples should pass strict test in our lab. )Production Lead time: it depends on customers' order quantity ( 30 working days after deposit).

3, Payment: (Can negotiate with customers, our usual practices are as follow)

4, Tooling:100% prepaid by T/T.

5, Parts:30% upon order confirmation and balance before delivery by T/T

Applications:

Aluminum profile used in cars, trains machinery ,electronics, medical and other industrial filed . In terms of hardware, machinery, electromechanical parts, solar PV products, aluminum frames are adopt as important auxiliary materials. We also have aluminum profiles for radiators, fitness machinery, buildings, lighting instrument, windpipes, oil pipelines, for instance.

Competitive Advantage:

1.good quality aluminium profile with economic price

2.15-year manufacturing experience

3.ISO9000

4.ODM or OEM

FAQ For Saving Your Precious Time!

Q1:What's the thickness for anodizing?Can you do 15um?

A:Our normal thickness is about 10 um.Yes, we can do 15um and above.

Q2:What color you can do for powder coating?The thickness for powder coat?

A:We can do any color for powder coat as long as you can provide the color sample.Our normally powder coating thickness is 60-80um.

Q3:What color you can do for wood grain?

A:Our most popular colors are Western Red Cedar, Australia Cedar, Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western Wood, Snow Gum, etc.If you need any other colors, we can do according to the color samples you provide.

Q4:How's the weather resistance for wood grain finish D1010?

A:(1).Powder:Akzo Noble Interpon D1010.

(2).Wood grain film:Italian Menphis.

(3).Standard complied:American AAMA Standard.2603

(4).UV test:1000 hours.

(5).Salt spraying test:1000 hours.

(6).Normal weather:10 years color guarantee.

Q5:What certification do you have?What's your standard?

A:We have ISO certification.Our standard is DIN, AAMA, AS/NZS, China GB.

Q6:What's the delivery time for samples and mass production?

A:(1).2-3 weeks to make the new moulds and make free samples.

(2).3-4 weeks after receipt of deposit and confirmation of the order.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!