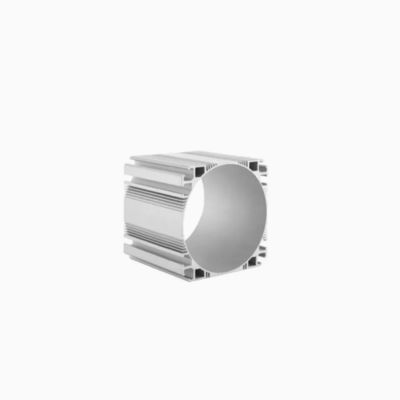

6063 6061 Customized CNC Machining Anodized Aluminum Electric Motor Housing/Shell Profile

Electric motor housing aluminum extrusion, also known as aluminum alloy motor shell or servo motor housing aluminum profiles, offers superior protection and performance for electric motors.

Key Features

- Raw materials: 6063, 6061, 6005, 6082 aluminum alloys

- Temper: T5, T6

- Surface Treatment: Mill finish, Anodized, Powder Coated, Wooden Transfer, and more

- Processing: Cutting, milling, punching, stamping, drilling, CNC machining

- One-stop Service: Mould design, Extrusion, Finishing, Fabrication, Assembly, and Delivery

- Packing: Carton and pallet packaging options

- Delivery lead-time: 15-25 days

- Customization: Various sizes and styles available with OEM/ODM support

Manufacturing Process

Die design → Die making → Extruding → Cutting → CNC Machining → Surface treatment → Packing

Packaging & Shipping

Products are packed with protective plastic film and sturdy wooden cases suitable for both sea and air shipment.

Technical Specifications

Chemical Composition:

| Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Impurity |

Al |

| 6063 |

0.2-0.6 |

0.35 |

0.1 |

0.1 |

0.45-0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

| 6061 |

0.4-0.8 |

0.7 |

0.15-0.4 |

0.15 |

0.8-1.2 |

0.04-0.35 |

0.25 |

0.15 |

0.15 |

Rest |

| 6060 |

0.3-0.6 |

0.1-0.3 |

0.1 |

0.1 |

0.35-0.6 |

- |

0.15 |

0.1 |

0.15 |

Rest |

| 6005 |

0.6-0.9 |

0.35 |

0.1 |

0.1 |

0.40-0.6 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

Mechanical Properties:

| Alloy |

Temper |

Tensile Strength |

Yield Strength |

Elongation |

| 6063 |

T5 |

≥ 160Mpa |

≥ 110Mpa |

≥ 8% |

| 6063 |

T6 |

≥ 205Mpa |

≥ 180Mpa |

≥ 8% |

| 6061 |

T6 |

≥ 265Mpa |

≥ 245Mpa |

≥ 8% |

Technical Support

Our engineering team provides comprehensive support throughout your project:

- Custom design services including CAD drawings and 3D models

- Design optimization to reduce production costs while improving performance

- Complete one-stop manufacturing from raw materials to finished products

- Strict quality control throughout the entire production process

Manufacturing Capabilities

Extrusion

With 44 aluminum extrusion lines including a 6800-ton unit, we produce industrial profiles up to 600mm in diameter for applications including radiators, fan blades, motor enclosures, and solar cell frames.

Anodizing

Our 6 anodizing lines produce uniform oxidation films in various colors (silver, black, gold, champagne, imitation steel) with enhanced corrosion resistance and hardness. Strict quality control ensures color consistency across batches.

Painting

Our 4 powder spraying lines use high-quality Gema Switzerland nozzles with environmentally friendly paints for durable, colorfast finishes.

CNC Machining

Our advanced machining center includes:

- 12 PRATIC machining centers for milling, drilling, and tapping long profiles (up to 6m)

- Wegoma automatic cutting machines for precise, efficient cutting

- 30 punching machines (50-100 ton capacity) for thick profiles

- 10 stretch/bending machines for precise angle forming

- 10 milling machines for complex plane machining

Quality Assurance

Finished products undergo strict inspection before being carefully packaged in our organized warehouse system, ensuring quality and traceability.

Certifications

Company Milestones

- 2004: Recognized Brand of the Building Industry Material Market

- 2006: ISO9001 Certification

- 2009: Jiangsu Famous Brand Certificate

- 2012: Established partnerships with Panasonic and LG

- 2015: Became supplier for BOSCH (Germany)

- 2019: Major supplier for world's largest heater manufacturers

- 2023: Expanding global distribution network

Notable Projects

Soccer City Stadium, Johannesburg: As the main aluminum supplier for Africa's largest stadium (94,000 seats), our materials contributed to this landmark project.

Lobster Trailers: Our R&D team collaborated with this Nordic trailer giant to optimize designs and manufacturing processes, reducing costs while improving performance.

Educational Furniture: Supplied aluminum legs for school desks, demonstrating our capability to support diverse applications through strong design and manufacturing expertise.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!