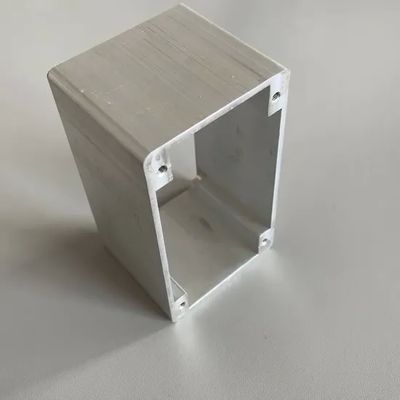

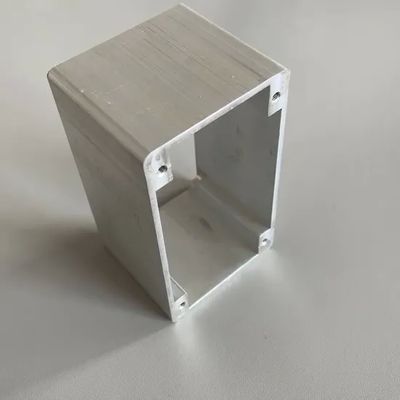

CNC Customized Aluminum Profile Enclosure Shell Electrical Housing

About Metalplus

Metalplus specializes in aluminum industrial profile design and manufacturing with a production base of more than 100,000 square meters and annual capacity exceeding 100,000 tons.

Product Navigation

Product Specifications

- Material: Aluminum alloy 6063, 6061, 6082, 6005 or according to requirement

- Temper: T5, T6

- Quality standard: GB5237-2008

- Surface treatment: Mill finish, anodized, powder coated, electrophoresis, sand blasting etc. PVDF coating, wood grain painting, matted, polishing bright

- Color available: Silver, Bronze, champagne, Matte, Natural for anodizing, Ral for powder coating

- Packing details: Protected film inside and shrinking film outside

- Samples time: two weeks after receiving the mold fee

- Delivery: 20 days after deposit

- Production Capacity: 100,000 tons/year

- MOQ: 1 TONS

- Payment terms: 1) T/T 2) L/C at sight

- Port: SHANGHAI PORT

- 17 press extruder

- OEM & ODM service

Manufacturing Process

Die design → Die making → Extruding → Cutting → CNC Machining → Surface treatment → Packing

Product Advantages

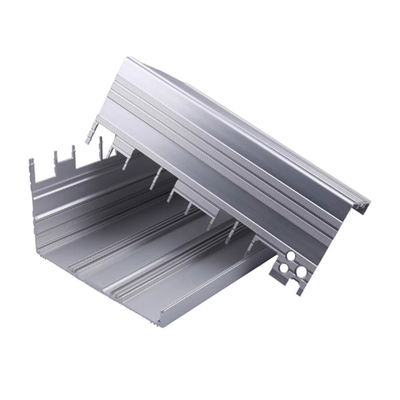

Superior Heat Dissipation

The aluminum alloy motor housing maintains temperature within optimal range during continuous operation due to aluminum's excellent thermal properties.

Lightweight Construction

Aluminum extrusion products significantly reduce weight for easier transportation and installation while maintaining structural integrity.

Excellent Plasticity

Aluminum alloys offer superior ductility and plasticity compared to steel and cast iron, allowing for more design flexibility.

Environmental Benefits

Our aluminum housing motors feature waterproof, dustproof, and corrosion-resistant properties with energy-efficient performance and long service life.

Technical Parameters

Chemical Composition

| Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Impurity |

Al |

| 6063 |

0.2-0.6 |

0.35 |

0.1 |

0.1 |

0.45-0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

| 6061 |

0.4-0.8 |

0.7 |

0.15-0.4 |

0.15 |

0.8-1.2 |

0.04-0.35 |

0.25 |

0.15 |

0.15 |

Rest |

| 6060 |

0.3-0.6 |

0.1-0.3 |

0.1 |

0.1 |

0.35-0.6 |

- |

0.15 |

0.1 |

0.15 |

Rest |

| 6005 |

0.6-0.9 |

0.35 |

0.1 |

0.1 |

0.40-0.6 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

Mechanical Properties

| Alloy |

Temper |

Tensile strength |

Yield strength |

Elongation |

| 6063 |

T5 |

≥ 160Mpa |

≥ 110Mpa |

≥ 8% |

| 6063 |

T6 |

≥ 205Mpa |

≥ 180Mpa |

≥ 8% |

| 6061 |

T6 |

≥ 265Mpa |

≥ 245Mpa |

≥ 8% |

Technical Support

- Our team provides comprehensive design support including CAD drawings and 3D models for customer confirmation, followed by custom mold creation and precision extrusion.

- For clients with existing designs, our R&D team optimizes for production efficiency and cost-effectiveness while maintaining performance requirements.

- Our one-stop service covers product design, mold customization, aluminum bar melting, extrusion profiling, precision machining, and surface treatment with strict quality control throughout the process.

Production Capabilities

Extrusion

With 44 aluminum extrusion lines including a 6800 ton unit, we produce industrial profiles up to 600mm diameter for applications including radiators, fan blades, motor enclosures, and solar cell frames.

Anodizing

Our 6 anodizing lines produce uniform oxidation films that enhance corrosion resistance, hardness, and wear resistance. Available in silver, black, gold, champagne, and imitation steel colors with custom options available.

Painting

Four powder spraying lines using Swiss Gema nozzles apply environmentally friendly paint with excellent adhesion and color retention.

CNC Machining

- 12 PRATIC machining centers handle complex profiles up to 6 meters

- Wegoma automatic cutting machines for precision cutting

- 30 punching machines (50-100 ton capacity) for thick profiles

- 10 stretch bending machines for precise angle bending

- 10 milling machines for various plane machining

Packing & Shipping

Finished products are carefully packaged with protective film and undergo strict quality inspection before shipment. Our organized warehouse system ensures accurate product tracking.

Certifications

Company History

- 2004: Recognized Brand of the Building Industry Material Market

- 2006: Certificate for Product Exemption from Quality Surveillance Inspection & ISO9001

- 2009: Advanced Company, Jiangsu Famous Brand Certificate, Credible Product of Quality in Jiangsu Province

- 2012: Established business relationships with Panasonic and LG

- 2015: Became innovative producer and supplying partner for European clients

- 2017: Developed new baseboard heater products

- 2019: Partnered with world's largest heater manufacturers as aluminum shell supplier

- 2023: Expanding overseas distribution network for mutual benefits

Notable Projects

Soccer City Stadium, Johannesburg: As main aluminum supplier for Africa's largest stadium (94,000 seats), our products contributed to this landmark project.

Lobster Trailers: Our optimized aluminum solutions for this Nordic trailer manufacturer demonstrate our design and production capabilities.

School Furniture Project: Supplied aluminum legs for school desks, showcasing our ability to support local education initiatives.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!